Our indexable deep hole drills cover a range of diameters from 16mm to 300mm.

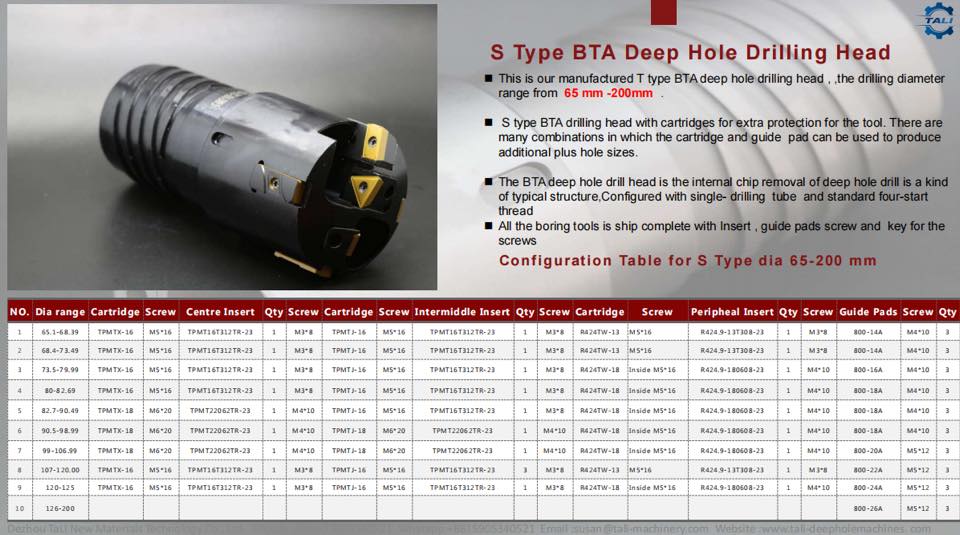

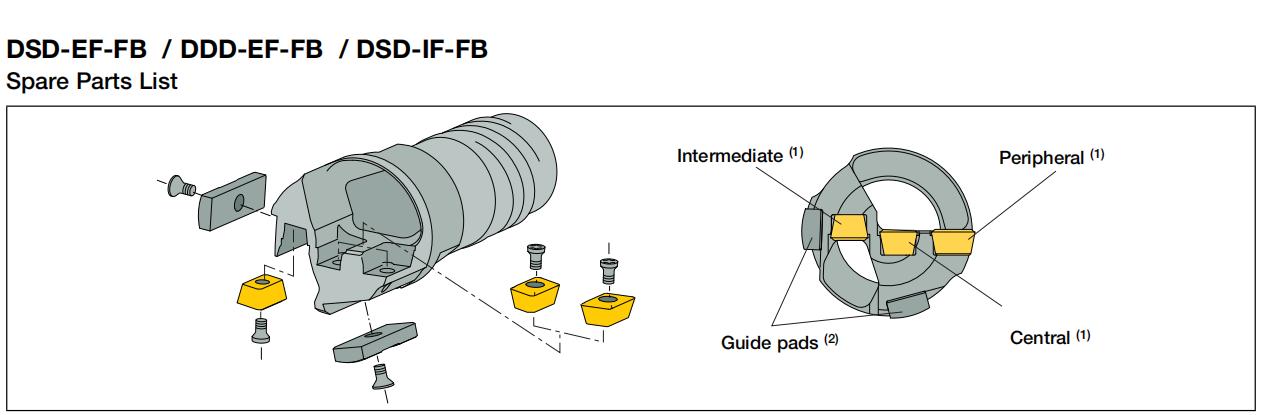

The BTA drill head is mounted on a long drilling rod using threads. It has multiple cutting surfaces for efficient chip removal with high pressure metalcutting fluid draining through a hole in the drill head and then out of the drilling rod.The BTA tool can be configured with either welded or indexable carbide inserts.doctorkong can provide B type, P-type clamped /welded deep hole drilling, reaming drill, complete set of drill pipe, and other non-standard deep hole machining tooIs. We provide more individualized deep-hole drilling scheme and technical support in deep hole machining application.Indexable drilling grades provide significant productivity increases and long tool life. With each cutting edge, you get excellent chip control, chip evacuation and surface finish

BTA drills have significant advantages in the field of deep hole processing, which are mainly reflected in the following aspects:

High-efficiency cutting: BTA drills adopt special tool geometry, which can continuously process high-precision hole diameter, cylindricity, straightness and high-quality inner surface holes at one time, thereby greatly improving processing efficiency.

Excellent chip removal performance: Through the internal chip removal design, chips and coolant can be discharged from the inside of the drill rod, effectively avoiding the problems of chip blockage and heat accumulation, and ensuring the stability and continuity of the processing process.

Strong adaptability: BTA drills can be equipped with different types of drill rods and drill bits according to user needs to meet the needs of different purposes, and have the advantage of one machine for multiple uses. At the same time, its drill pipe design has high torsional rigidity and can adapt to complex large-diameter deep hole processing.

High-precision processing: Because BTA drills have a self-guiding function, they can ensure tool balance and guide the direction of deep hole tools, so high-precision processing effects can be achieved.

Convenience and maintainability: The cutter head design of BTA drills is convenient and detachable, which is easy to replace and maintain. In addition, its overall structure has also been optimized, reducing the demand for functional components and reducing maintenance costs.

In summary, BTA drills have significant advantages in the field of deep hole processing. They can improve processing efficiency, ensure processing quality, and reduce maintenance costs. Therefore, they are widely used in various deep hole manufacturing scenarios

Post time: Sep-07-2024