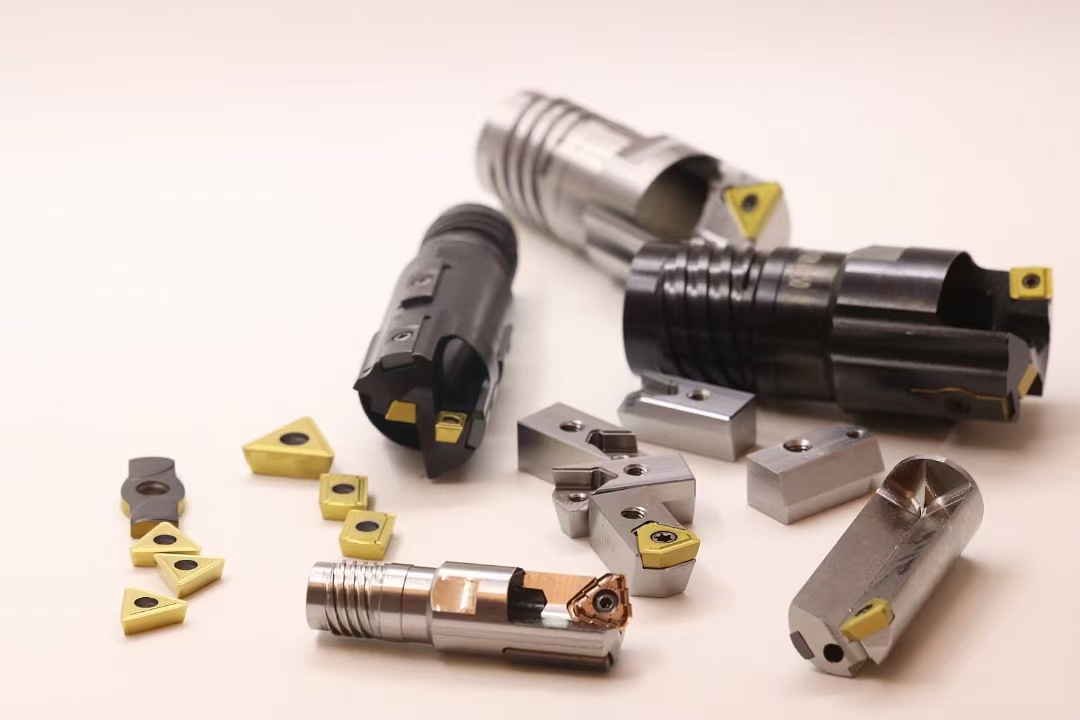

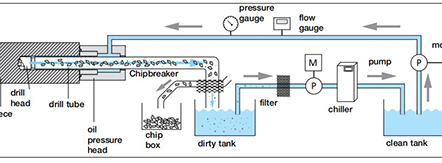

Deep hole drilling machining is a machining difficulty, high technical content, strong degree of specialization, high processing cost of a hole processing technology, generally only a higher degree of specialization, strong technical force of the production unit has this processing capacity, due to the oil, aviation, military, and construction machinery and other industries to use a large number of deep-hole parts, Generally, in such large production units, there are a certain scale of deep-hole processing workshops, and there are larger production batches and output value every year. Deep hole processing technology is different from the traditional processing method of drilling with twist drilling, generally to use special deep hole drill (such as gun drilling, internal chip deep hole drilling, nesting drill, etc.), special machine tools and complex accessories to complete, in the processing to use a large number of circulating cutting fluid (such as special deep hole cutting oil (liquid) or oil) to complete chip removal and cooling, lubrication tools. The consumption of cutting fluid is large (mainly taken away by chips), which will not only cause oil pollution to the processing site, threatening the health of the operator, but also the treatment of iron filings with oil will cause secondary pollution of the air and the environment, increasing manufacturing costs, therefore, how to reduce processing costs and eliminate environmental pollution is an important development direction of deep-hole processing technology research. If you can use dry processing technology for deep hole processing, it will be a good solution to the above problems. Due to the special requirements of deep hole processing, the use of completely dry cutting (that is, completely without the use of cutting fluid) is difficult to achieve in actual production, because in deep hole processing, the tool relies on the self-guiding role of the guide block to work, the guide block and the hole wall due to mutual extrusion will produce greater friction, in the traditional wet deep hole processing, The high pressure cutting oil will form an oil film between the guide block and the hole wall, which plays a lubricating role during processing and reduces the friction. If there is no oil film, the guide block will soon be worn and torn, resulting in cutting vibration or cutting, in addition, deep hole processing is carried out in a closed space, the tool chip removal channel is longer, the cutting heat generated in the processing is much larger than the ordinary turning process, and can not be like the ordinary dry turning process, by increasing the cutting speed to speed up the heat dissipation (which will cause no chip removal and sharp tool wear), Therefore, the most feasible research idea of using sub-dry method for deep hole processing is to use compressed air to drive trace cutting fluid in processing, after mixing atomization, it is transported to the cutting zone through the channel between the hole wall and the drill pipe, and high-speed injection to the tool chip contact area, giving full play to the cooling and lubrication of the cutting fluid, and at the same time, high-speed compressed air helps the iron chips to be discharged outward. Complete the production process, in the processing, the cutting fluid can almost be completely adsorbed between the guide block and the hole wall and the tool chip contact area, give full play to the efficacy of the coolant, save the use of cooling oil (liquid), eliminate environmental pollution, in line with the current national economic sustainable development of the strategic policy, has certain practical significance, in economic terms, can save a lot of manufacturing costs, The social benefits it creates (reducing environmental pollution and health hazards to operators) will be even more significant

Post time: Nov-11-2024