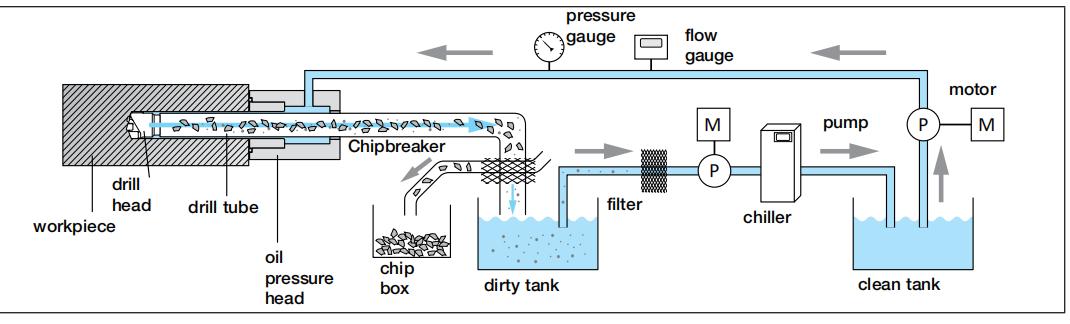

Deep hole drilling technology principle The operation of deep hole drilling on ordinary lathes. The machined part is positioned by a V-shaped iron on the lathe's large drag plate and is clamped by a bolt press plate. During drilling, the drill pipe is clamped by a special chuck in the spindle and rotated under the drive of the spindle, and the parts are driven by a large drag plate for feed movement. A fluid feeder is installed on the machine bed and is sealed to the left end face of the component using an O-ring. The pressurized cutting fluid is injected into the inlet of the fluid feeder, flows into the cutting zone through the gap between the outside diameter of the drill pipe and the hole wall, and cools the tool. The chip is discharged from the drain box with the cutting fluid through the outlet of the exclusive chuck in the hole of the drill pipe

BTA deep hole drilling tools Drill Heads-professional manufacturer for deep hole drilling solutions and tools. doctorkong has the engineering expertise and manufacturing capabilities to meet most of deep hole machining requirements.

Post time: Sep-07-2024